Cable assemblies from LQ Complete installation systems for mechanical and plant engineering

When it comes to installation technology in mechanical and plant engineering, you have to talk to component suppliers from the electrical, mechanical, hydraulic, pneumatic and assembly sectors. You have to obtain and check quotations, clarify specifications and costs, take care of prototype construction and documentation, order processing and spare parts supply, right through to completion and assembly of the cable assemblies.

Or you can talk to us. As a successful system and product supplier, we at LQ have specialized in offering our customers complete installation systems. Which makes things easy for you: You only talk to one company instead of many. You have one partner who takes care of all the details of the machine installation, who talks to the suppliers and who delivers the complete installation to you ready for assembly. This gives you major advantages in terms of quality, time and costs.

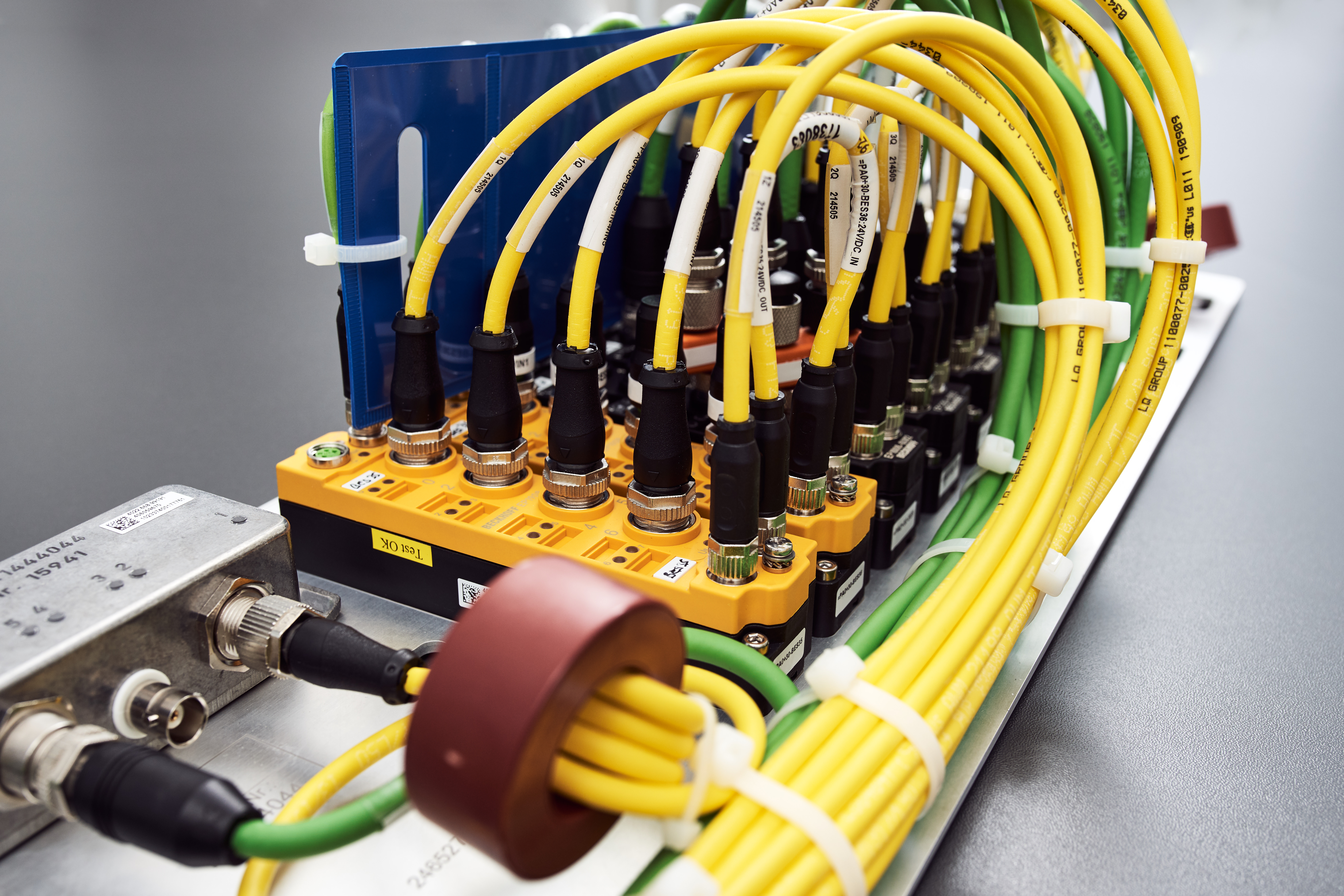

Function tested installation technology According to the Plug&Play principle

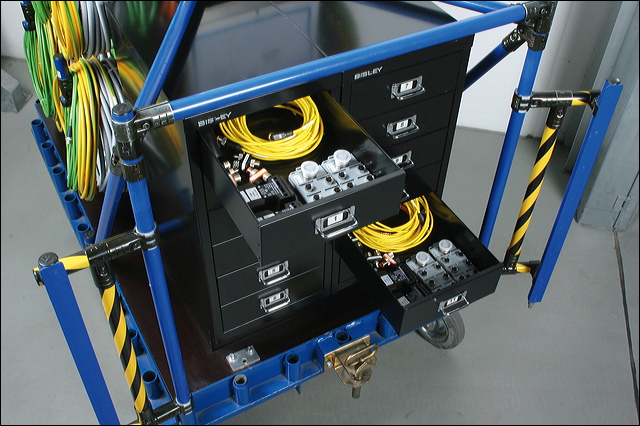

We deliver the ready-to-install cable assemblies on machine-specific transport racks. This simplifies goods receipt - only one complete part needs to be recorded and not broken down into many small items. The compact and ready-to-install delivery also facilitates integration into the existing machine geometry. The clear identification of source and destination enables quick and easy connection according to the plug-and-play principle. This significantly reduces the assembly lead time - from several days to just a few hours.

Standard or special assemblies Cable confection and cable assemblies from LQ

At LQ, we develop cable assemblies of all kinds for a wide variety of applications. Whether standard or special assemblies, we design and produce high-quality cables and wires up to the ready-connected plug. Our cable assemblies are used in a wide variety of industries.

Do you have individual requirements in the field of cable assemblies? We have the ideal solution for you. Benefit from our many years of experience and the highest standards of quality and service.

Assembled cables according to Siemens and Bosch standard Standard cables from LQ

On request, we manufacture assembled cables according to Siemens standard 6FX8002 and Bosch standard, in all common variants for different motors and in a wide range of cross-sections.

Always according to current index Everything exactly according to your needs

At LQ, the satisfaction of our customers is our top priority. We assemble according to your wishes and ideas and are fully flexible. Thanks to our fast change service, we can deliver corresponding assemblies in the afternoon for specifications that are passed on in the morning.

Constant high quality DIN EN ISO 9001:2015

We manufacture individual and high-quality cables quickly and uncomplicatedly at a fair price. In doing so, we place particular emphasis on high quality through optical and electrical testing procedures, both for small series and for large quantities. Consistent quality management ensures a permanently high level of quality and a two-year product guarantee.

Reference projects Cable assemblies and cable confection from LQ

CHIRON Predefined installation assemblies

For Chiron Werke GmbH & Co. KG we hold servo cables according to Siemens and Bosch standards. We deliver the ready-made installation assemblies with brand-original products on handy pendulum racks.

WAFIOS FUL 36 For Wafios AG we supply cable harnesses including assembly of the cabinet bushing

All cables and assemblies are 100% tested by us for completeness and functionality - for every order. Short delivery times and high adherence to delivery dates guarantee highest customer satisfaction.

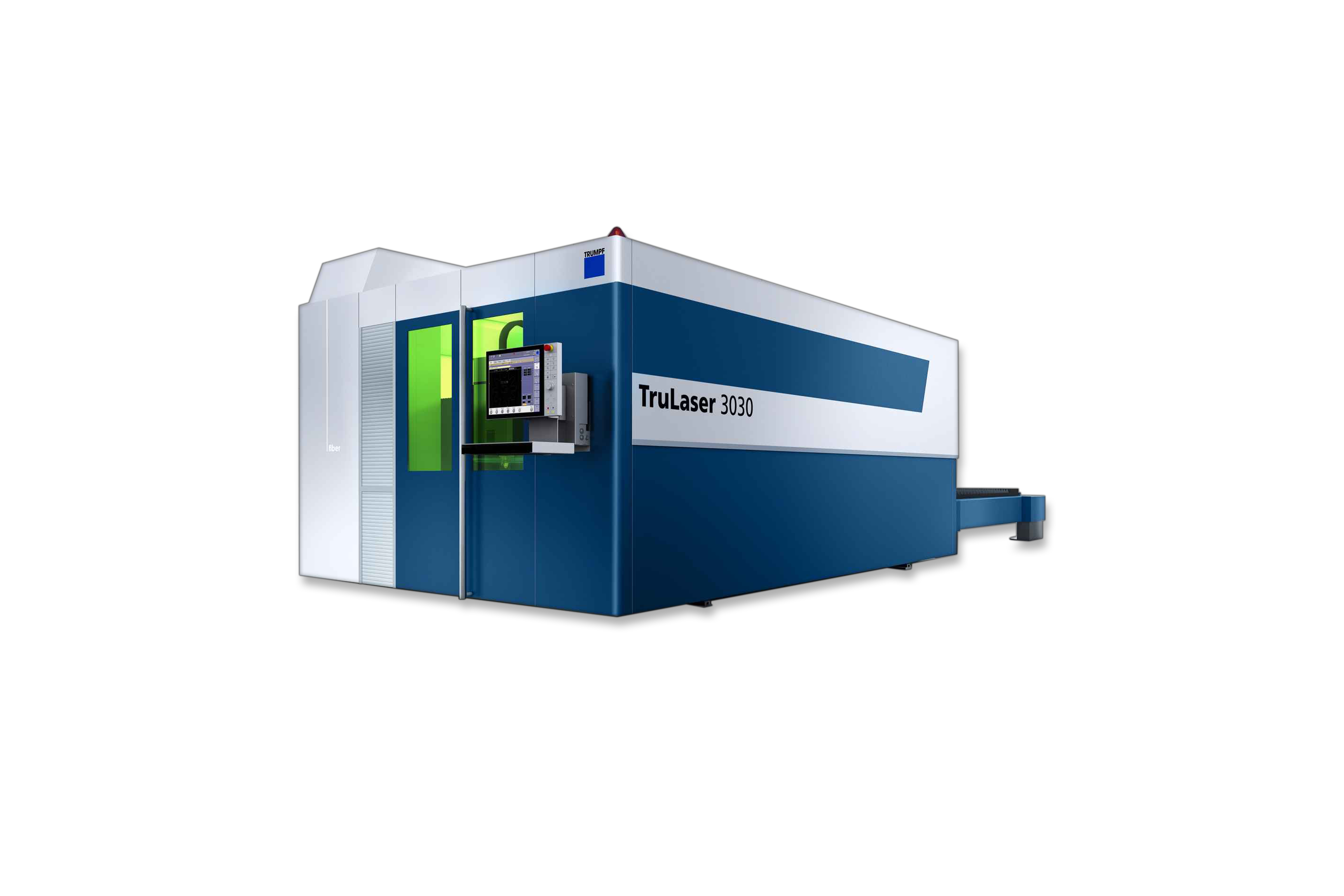

TRUMPF TruLaser 3030 We guarantee state-of-the-art order logistics for cable harnesses for Trumpf GmbH + Co. KG

Cable harnesses on practical transport trolleys ensure fast installation in series production. A high degree of automation in the production of the cable assemblies ensures consistently high quality.

Interesting facts about cable confections and cable assemblies

What is cable assembly?

During cable assembly, the connection ends of raw cables cut to length are processed. This is a complex process involving a wide variety of connectors and end finishes (open ends). The result of this processing is ready-to-connect cables, which are referred to as cable assemblies. These are used wherever electronic signals need to be transmitted. The spectrum ranges from single-conductor cables to multi-pole cables.

Where are cable assemblies used?

Assembled cables have a wide range of applications, both in the private and professional sectors. Assembled cables must meet special requirements, particularly in industrial processes. For this reason, customer-specific assembled cables with a high degree of variability are primarily used. The areas of application range from automation technology and mechanical engineering to medical technology.

Thanks to our many years of experience in the field of cable assembly, we are also equipped to meet the special requirements of various industries and assemble individual cables on request. We offer a wide range of products – from large series (e.g., servo cables) to small series and customer-specific cable assemblies.

What needs to be considered when assembling cables?

The production of assembled cables often varies, as cables and cable assemblies must meet individual requirements and functions depending on the type of application. Initially, certain geometric and electronic specifications are followed. The cross-section of the assembled cable is determined and the cables for which the cable will be used are specified. It is important to calculate the maximum bending radius in order to prevent cable breaks and ensure high quality. Production must therefore be very precise but also simple so that the cable can be replaced as quickly as possible in the event of damage.

When assembling cables, it is important to comply with the prescribed DIN standard in the manufacturing process. Among other things, the environmental conditions, shielding, material, configuration of the conductors and cables, and the shape of the connector must be taken into account. All of this has a major influence on cable assembly. Ultimately, it is the functionality of the product that counts, which is why it must be thoroughly tested before sale.

What does the production of assembled cables look like?

Cable assembly at LQ involves four important steps: printing the order, cutting to length, stripping, and assembly. In the first step after printing, the required cables are cut to the desired length. Each cable has a so-called sheath, which is removed with special pliers. This process is called “stripping.” Stripping is followed by assembly. This involves stripping the individual strands, crimping, and assembling the connectors. Stripping involves removing the insulation from the individual strands without cutting or damaging them. This is followed by crimping the ferrules. Crimping comes from the English word “to crimp,” which means “to press” or “to squeeze.” Here, the metal sleeves are pressed individually onto the strands. These sleeves create a connection between the cable and the connectors. Finally, the connectors are assembled and subjected to an electrical test.

In addition to manual assembly, some cables are manufactured and overmolded by machine. For this purpose, the cables are fitted with different plugs and contacts, which are manufactured in a molding machine. There are various mold inserts that can be used and replaced repeatedly, depending on the type of plug.

Which connector solutions are used in cable assembly?

We use various connectors in our cable assemblies. Different plugs and connectors are used depending on the area of application and specific requirements. When you place an order for a cable assembly with LQ, we will advise you individually in advance on the options available and find the optimal solution for your requirements.

The following connectors are used in assembly at LQ, among others:

- Round connectors

- Rectangular connectors

- SUB-D connectors

- Data connectors

- PCB connectors

- Coaxial connectors

- AV connectors

- Power connectors

- Signal connectors

- Data connectors

Depending on the application, cables with end fittings on one or both ends may also be necessary. End fittings can be:

- Wire end ferrules

- Ring/pin/fork cable lugs

- Crimp contacts

- Flat plug sleeves

Furthermore, one or both cable ends could also be prepared:

- Cut smoothly

- Stripped to the desired length with or without shrink wrapping

- The wires partially stripped

- Individual or multiple wires insulated

- Shield exposure at the cable end or also cut to size in the middle of the cable

Here you will find further information on various topics related to cable assembly:

Requirements for customer-specific cable assembly services

Applications of assembled cables in various industries

Selecting the right cable type for an application

Automation and craftsmanship in cable assembly

Flexible flat cables and their applications

Integration of cable assembly into overall production processes

Cable management and organization

Cable connectors and their selection

Quality assurance in cable assembly

Trends and developments in cable assembly

Environmental aspects in cable assembly

Differences between handmade and machine assembly

Your contact