Types of Connectors and Their Applications

Connectors are indispensable components that find application in almost all electrical or electronic devices. They serve to connect and disconnect electrical wires. The connection parts are aligned correctly through the form-fit of the plug parts, fixed in place by spring force in a friction-locking manner, and often secured against unintentional disconnection by screwing. Distinctions are made between standards for the geometric shape of plugs, sockets, couplings, and outlets, and standards for the electrical signal transmitted through cables. They come in countless designs and variations, such as single-pole connectors for transmitting high currents or multi-pole models for connecting three-phase consumers.

A connector generally consists of two parts:

- A female part with inward-facing openings for the contacts. If this part is at the end of a cable, it is called a coupling. When permanently installed in a housing or wall, it is referred to as a socket.

- A male part with outward-facing contact pins. If this is attached to a cable end, it is called a plug. When permanently integrated into the housing, it is referred to as a built-in plug.

Connectors are classified into signal and power connectors. Signal connectors are used for connecting components and their communication. Power connectors are used when, for example, supply currents for driving a motor need to be transmitted. Signal connectors are less powerful compared to power connectors and primarily serve the transmission of signals and communication. The signals transmitted through cables and connectors are also subject to standards such as UL, low voltage directives, or EMC.

Areas of Application for Connectors

Connectors are used in various industries. Depending on the application area, they need to be robust and resistant to moisture, dust, and temperature. There are hardly any industries that can do without connectors.

Application Areas of Connectors:

- Automotive Applications

- Data and Communication Technology

- Medical Technology

- Industrial Electronics (machinery and plant engineering, production, material handling)

Electrical Connectors These connection techniques are available

Cutting connection

The cutting connection enables quick connection without soldering, screwing, or stripping. The integrated cutting clamp locks the cable inserted into the housing and connects the cable to the conductive contact.

Crimp Connection

In a crimp connection, the wire and contact are connected using a crimping tool. Crimping is particularly useful for connections that must withstand harsh environmental conditions such as temperature fluctuations, vibrations, or high tensile stress.

Screw Connection

The screw connection allows for a quick and easy connection of the plug and wire using screw terminals. Circular connectors with integrated screw locking are also referred to as screw connections. This prevents unintentional disconnection of the connection.

Pierce Connection

The pierce connection is a technique that requires no prior treatment of the conductor. The conductors are pushed into the designated guide in the connector's cover. The pierce contacts penetrate the insulation of the conductors when closed, ensuring a secure conductor connection. This technique is particularly useful for simple field installations.

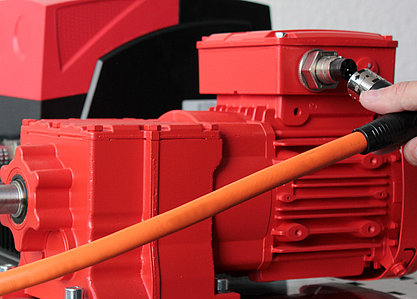

Circular Connectors

Circular connectors refer to the round shape of the plug. They are commonly used for signal and power transmission in industries, aerospace, and aviation.

Rectangular Connectors

Rectangular connectors are used in junction boxes and control cabinets and are primarily utilized in mechanical engineering, transportation technology, and energy generation.

PCB Connectors

PCB connectors allow for a universal connection of printed circuit boards across various industries and markets. They lock using snap-in systems or screw flanges.

Coaxial Connectors

Coaxial connectors are used in high-frequency applications up to 4 GHz, as well as in audio and video technology and data transmission.

Versatile and functional Circular Connectors from LQ

Our range of different circular connectors allows for a reduction in space requirements while simultaneously increasing current-carrying capacity. We offer power and signal connectors in sizes 15, 23, and 32. The X-TEC 15, with its compact connector diameter of 15 millimeters, opens up numerous application possibilities for machine, aggregate, and equipment manufacturers, as well as in conveyor technology. The compact and round design enables use even in confined spaces. Whether straight or angled housing, with screw-in thread or mounting socket, our X-TEC connector can be flexibly mounted at different angles.

About our products