Definition: What is Kanban?

Kanban is a method of production planning and control that regulates material orders according to the consumption control principle (Pull Strategy). This means that material supply is based solely on the consumption of the production process. The word Kanban is Japanese and translates to "card," "signal card," or "board," which serves as an indicator for the production or replenishment process.

The History of Kanban

The Kanban system was developed in 1947 by Japanese Toyota engineer Taiichi Ohno. He realized that he could improve the Toyota Production System by aligning production with actual rather than forecasted demand. This Just-in-Time principle allows for products to be manufactured and delivered only based on current customer demand, thereby avoiding overproduction. The "Just-in-Time" production is based on the pull control principle and replaced the push-based production process. Products were no longer "thrown" onto the market but produced based on customer demand.

Rules and Principles of the Kanban Method

For the Kanban method to work effectively, there are several rules that must be followed:

- Establish Clear Rules: Rules should be clearly defined and understood by all participants. Each phase on the Kanban board must be defined.

- Task Limits: The number of available cards should be limited and aligned with the number of tasks. This helps manage workload and prevents overloading.

- Workflow: The Kanban board must be continuously updated. Tasks should always be in progress to maintain momentum.

- Continuous Improvement: Kanban processes should be regularly analyzed and optimized to improve efficiency and workflow.

- Leadership: All employees must take responsibility for maintaining the workflow and adhering to the Kanban process.

In addition to these Kanban rules, there are four fundamental principles:

- Start with What You Are Doing Now: Implement Kanban based on current processes rather than trying to overhaul everything at once.

- Make Evolutionary Changes: Changes should be gradual and incremental, allowing for adaptation and improvement over time.

- Respect Current Processes and Responsibilities: Understand and work within existing processes and roles before making changes.

- Encourage Leadership at All Levels: Leadership should be promoted across all levels of the organization to ensure the Kanban system's success and adherence.

Kanban in Production Process Control

Given the global flow of goods and supply chains, the Kanban method is a very important topic, as customer demands continue to rise. With this method, material flow can be made more efficient and production control improved. This allows for faster manufacturing and increased customer satisfaction.

The Different Types of Kanban and Their Uses

In production control based on the pull principle, various types of Kanban can be used. The method is not limited to manufacturing but is applied throughout the entire process from supplier to customer. As a result, different types of Kanban can be defined:

- Supplier Kanban

- Transport Kanban

- Production Kanban

- Finished Product Kanban

- Customer Kanban

How the Kanban System Works

In the Kanban system, cards are used to record information about withdrawal, transport, and production. By using the Kanban principle, required materials can be ordered, manufactured, and moved in the exact quantity needed.

The Kanban card is the heart of the Kanban system, as it identifies the material consumed in production. When materials are needed, an employee attaches the relevant card to the designated Kanban container. Logistics personnel then walk through the production area, collect the card, refill the container, and return it to its storage location. Meanwhile, the second container automatically moves forward. While one container is in production, the other is in storage. When empty containers are exchanged for full ones, the cards are placed back in their original location in the box. This creates a continuous cycle.

Kanban Cards and Kanban Boards

There are various types of Kanban cards, such as:

- Inventory Kanban: Triggers a replenishment.

- Supplier Kanban: Triggers a new order.

- Production Kanban: Leads to in-house production.

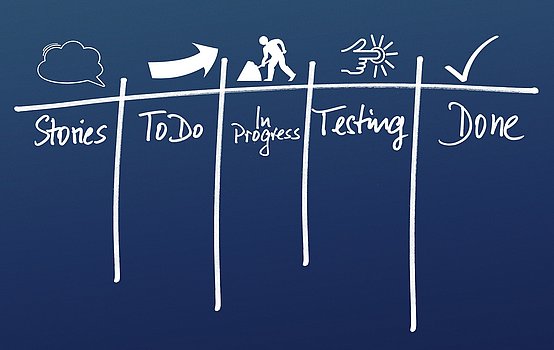

A Kanban board is a tool used to visualize different production processes, making it easier to manage workflows. By using sticky notes, each team member can be assigned a specific color. These notes list the tasks that still need to be addressed, making it quickly apparent who is responsible for which tasks. This applies to both individuals and entire teams. The Kanban board provides an overview of the work status. There are no specific guidelines for its layout, so it can be customized according to needs. Kanban teams often use an additional subdivision for prioritization. For example, a top section, known as the Fastlane, can be used to list tasks that need to be addressed more quickly than others. Below this, less urgent tasks can be listed. The Pull method is also used here: only when the team has available capacity in their column can team members take on a new task in their column.

Advantages and Disadvantages of the Kanban System

- Reduces inventory levels.

- Shortens throughput times within the company.

- Increases productivity and employee motivation due to higher responsibility.

- Easily compensates for minor fluctuations in quantities.

- Reduces capital binding.

- Enhances delivery readiness.

- Unsuitable for single-piece production.

- Unsuitable for production processes with a high variety of variants → highly fluctuating material demand.

- Increased deviations in quantities are not accounted for and can disrupt the entire process.

- Misplacement of containers or cards can lead to incorrect deliveries → rectification costs a lot of time and money.

Requirements for Kanban

Kanban can be implemented wherever there are sufficient processes that can be visualized. Certain personal, technical, and organizational prerequisites are necessary. An essential role is played by the qualification and motivation of employees, quality assurance, a flexible and manageable workshop organization, and the adaptation of the production program.

Where is the Kanban Method Applied?

Today, the Kanban tool is used in various areas, such as controlling material flows in logistics and information flows in IT, as well as in project management to oversee project progress. It is also applicable in marketing, sales, or human resources and is ideal for managing personal tasks. Personal Kanban is a method that helps individuals make conscious decisions about their actions. This allows all activities in work and personal life to be easily managed and optimized. Marketing Kanban, on the other hand, refers to the number of tasks. A central board shows which tasks still need to be worked on, are in progress, or have already been completed. Additionally, there is the so-called WIP (Work in Progress) limit, which regulates the maximum number of tasks that can be in progress at any given time.