M8, M12, M15, M23, M40: Standard Sizes for Various Applications Established standard sizes for different areas of application

Over the years, various connector sizes have become established in the machinery and plant engineering sectors for different applications. These sizes are based on the outer diameters of metric threads. Unlike older Whitworth or imperial threads, these standardized metric threads are defined by the ISO 1502 standard at the international level and detailed in the DIN standards DIN 13 and DIN 14 at the national level.

Typically, circular connectors feature an outer diameter that corresponds to a metric thread size where the plug and socket elements engage. This ensures compatibility between any pin and socket of the same size and coding within the application. The most commonly used sizes in machinery and plant engineering are M8, M12, M23, and M40. In the sensor-actuator sector, sizes based on imperial measurements, such as 7/8-inch external threads, are also common.

Similar to everyday screws that generally have standard threads, connectors require a matching coupling nut for attachment. The prescribed thread sizes for fine threads are specified in the DIN 13-1 standard. This standard details the thread tap required to drill the internal thread of the coupling nut so that it fits the corresponding external thread of the connector or screw. In machinery and plant engineering, coupling nuts with metric fine threads have become the standard connection method for connectors.

At LQ, we specialize primarily in automation technology and have developed our X-TEC circular connectors for the respective application areas. The X-TEC circular connectors feature a patented quick-lock connection and are therefore not listed under the "M" designation, as they do not have a metric thread but are designed according to the size of metric threads as described above. Our X-TEC circular connectors are available in sizes equivalent to the M15, M23, and M40 series. They are designated as X-TEC 15 (or M15 Power) for plug-cable assemblies, X-TEC 23, and X-TEC 32 (equivalent to the M40 series dimensions). In the context of cable assembly, we offer all common sizes, designs, and connection types.

At LQ, we specialize primarily in applications in automation technology and have developed our X-TEC circular connectors for the respective requirement areas. The X-TEC circular connectors feature a patented quick-lock connection and are therefore not listed with the designation M, as they do not have a metric thread, but are based on the size of a metric thread as described above. Our X-TEC circular connectors are available for the equivalent sizes of the M15, M23, and M40 series. They correspond to the designations X-TEC 15 or M15 Power as a plug-cable assembly, X-TEC 23, and X-TEC 32 (corresponds to the dimensions of the M40 series). However, we offer all common sizes, designs, and connection types as part of our cable assembly service.

There is a fundamental distinction between metric coarse threads (M) and metric fine threads (MF). The primary difference between the two types is that the fine thread has a narrower and less deeply cut thread profile. This can be attributed to the smaller pitch of the thread flanks. Over a given thread length, a fine thread therefore has more thread turns than a coarse thread. This makes the fine thread more space-efficient and allows it to develop more tensile strength with the same tightening torque.

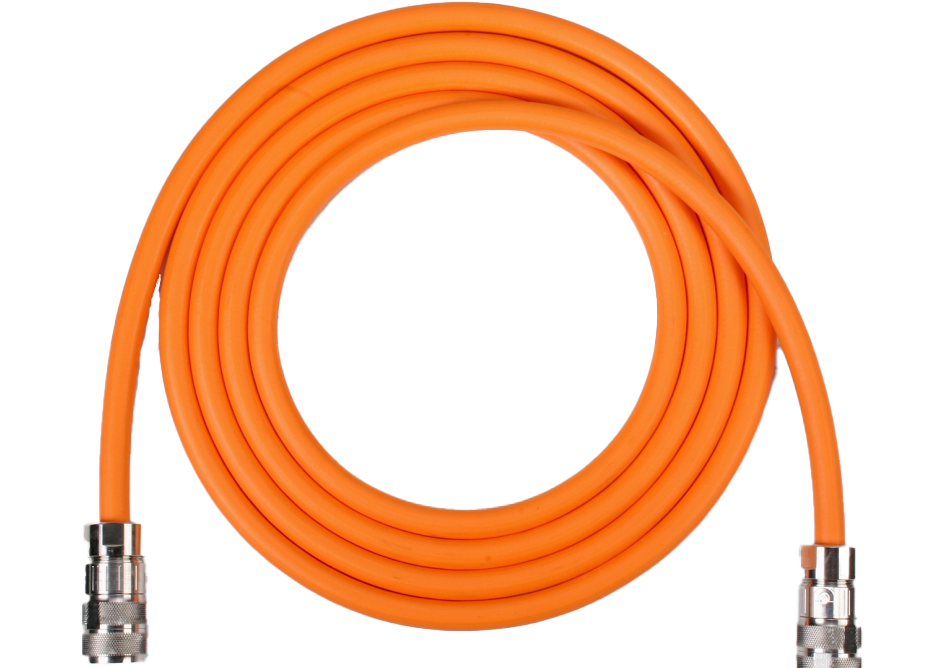

The Right Thread for Your Motor

Depending on the application and requirements, connectors come in various sizes and contact configurations. For actuator-sensor cables, circular connectors with M8 or M12 threads are commonly used. These are significantly smaller and feature less robust contacts. For driving and controlling asynchronous and three-phase motors as well as frequency converters up to 7.5 kW, we have developed the X-TEC 15. This circular connector can be directly attached to the motor via the M20x1.5 thread, replacing the more complex cable gland. For more demanding applications in automation technology, such as with servomotors, M23 series connectors are used. These are considerably larger and more robust than the smaller series connectors and feature more powerful contacts.

Besides the size, the correct contact configuration is crucial for compatibility. Generally, there are power connectors and signal connectors. Power connectors are primarily used for driving and controlling motors, while signal connectors are used for transmitting signals and measurement data. Since there are many different manufacturers of circular connectors, each with its own contact configuration, compatibility is not always guaranteed. Consequently, manufacturers like Bosch, Siemens, and Fanuc have become unofficial market standards.

For high-power three-phase consumers, M40 connectors are used. They are significantly more powerful and larger than the M23 series connectors and support consumers with a nominal current of up to 60 amperes or a nominal voltage of 630V for power contacts and 250V for signal contacts (X-TEC 32 values).

At LQ, we offer the appropriate X-TEC circular connector for each of these application areas or, as part of our cable assembly services, a wide range of different connector options upon request.

How Easy It Is to Work with Our Connectors

All connectors from LQ feature a specially developed and patented quick-locking system. This allows interfaces to be connected easily and conveniently using the plug-and-play principle, without the need for separate tools. This applies whether it’s M20, M23, or M40 series applications. Machines and systems can be connected and put into operation in no time. In case of a fault or malfunction, this system helps to significantly reduce machine downtime. Once the issue is identified, the affected components can be simply disconnected and replaced.

More informationWith Our Circular Connectors, You’re on the Safe Side

Whether with our own products or within our cable assembly services at LQ, we meticulously ensure flawless quality when selecting individual components. All products undergo extensive optical and electrical testing before delivery. This guarantees that only 100% functionally tested components reach our customers.

Thanks to our high quality, our connectors are primarily characterized by their durability (guaranteed for over 500 mating cycles) and exceptional shock and vibration resistance.

All connectors are always sealed and securely connected, with no play in the mated condition. With high temperature ranges from –20°C to +130°C (X-TEC 23/32), our circular connectors are also suitable for industrial applications in harsh conditions.