For higher power requirements, such as in industry, production, or electrical machines, electric motors are not operated with alternating current but with three-phase alternating current, also known as "three-phase current."

In such cases, the three-phase motor, also called an asynchronous motor, is used.

From Rotor to Bearing - The Structure of a Three-Phase Motor

To understand how a three-phase motor works, it is helpful to understand the structure of the motor and its various components.

Rotor

The moving part is the rotor, also known as the armature or rotor. There are two different types of rotors for an asynchronous motor. One type is the squirrel-cage rotor, where the conductor bars have low resistance and are short-circuited at the ends in a ring shape. Usually, the slots in the laminated core are filled with aluminum or copper conductor bars.

Another possible rotor design is the wound rotor. The rotor winding is not short-circuited but is connected to the outside via slip rings. External resistors can be switched in via step switches, which affect the speed and torque.

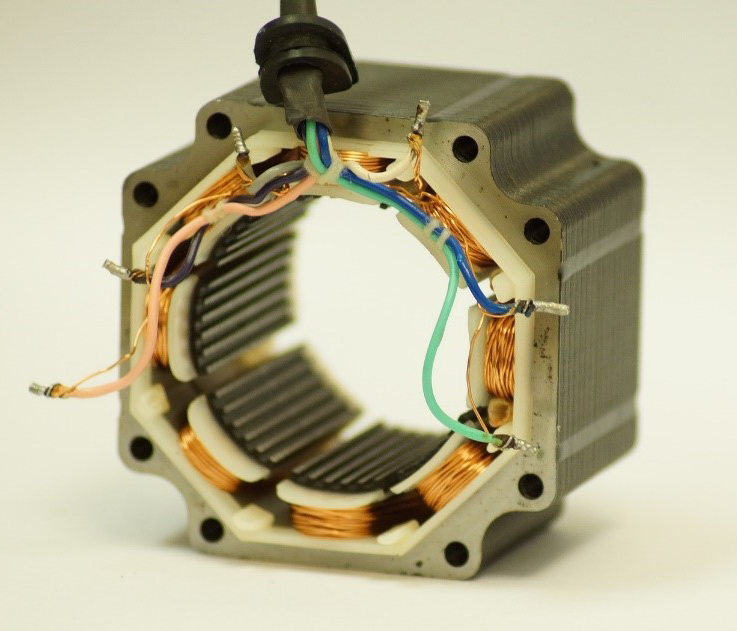

Stator

In a three-phase motor, the stator consists of three or more coils, each energized by a phase of the line voltage. Three-phase current means that the phases of the three coils are shifted by 120 degrees relative to each other. Since the stator coils of a three-phase asynchronous motor are also arranged in a circle and shifted by 120 degrees, a magnetic field is generated that rotates around the rotor axis with the frequency of the applied voltage. The rotor and stator are the two main components of the three-phase motor structure.

Motor Housing

Depending on the power, the motor housing can be made from different materials. Aluminum castings are used for motors with small to medium power, while cast iron is used for higher-power motors. Often, radiators are integrated into the housing, which increases the surface area of the housing. As a result, the heat of the three-phase motor can be dissipated more efficiently.

Bearing Shields

The bearing shields are the A-side and B-side covers of the motor housing. The A and B sides of the motor housing are perpendicular to the rotor axis. They protect the motor and the interior of the machine from contact and are responsible for securing the rotor shaft. The end caps are precisely integrated into the housing to ensure a uniform air gap between the stator and rotor.

Shaft

The rotor core is mounted on a steel shaft. The shaft passes through the end caps. On the A-side, the drive shaft extends through the end cap. On the B-side, the shaft drives other systems such as a fan, or a mechanical brake may be attached here.

Fan

The shaft drives the fan on the non-drive side. It directs the airflow generated by the rotational movement through the cover back to the cooling fins of the motor housing.

Bearings

The bearings installed in the bearing shields are responsible for connecting the rotating and stationary parts of the three-phase motor housing

The Operation of the Three-Phase Motor

Three-phase motors operate with what is known as three-phase current, also called high voltage. Specifically, this type of electrical energy consists of three separate alternating voltages that are sent out at different times on three separate lines. These three alternating voltages are applied to three different coils, which are operated either in a delta or star configuration. Due to the time offset of the sinusoidal oscillations of the alternating voltage, three magnetic fields are generated in the three coils of the motor, which also rise and fall in time. This creates a rotating magnetic field within the motor. At the center of these three coils is the rotor, which is made of magnetic material. The rotating magnetic field turns the rotor according to the timing of the three magnetic alternating fields. Since the rotor lags behind the rotating field of the stator, the speed of a single-pole motor at a network frequency of typically 50 Hz is below 3000 revolutions; this difference is referred to as slip.

What Happens with Incorrect Connection?

The motor can be easily damaged if it is not connected correctly. For example, if the voltage in the winding exceeds the maximum allowable value, the insulation can be damaged.

Powerful and Low Maintenance

The main advantage of this type of motor is its very high energy efficiency of up to 80%, which is significantly higher than that of direct current motors. Additionally, three-phase motors are known for being powerful, robust, and low maintenance. Due to their sturdy construction, they are extremely versatile and can be used in a wide range of machines.

Three-phase motors for industrial and commercial applications

Three-phase motors have a wide range of applications. Thanks to their robust design, they can be used in a wide variety of machines. They are used in precision machines and many industrial applications such as tools, pumps, fans, conveyor belts, and even railway drives. These motors are also very commonly used in the manufacture of machines in factories.

FAQs – Frequently Asked Questions

Is a three-phase motor an alternating current motor?

An AC motor is an electric motor that runs on alternating current. Depending on the type of alternating current, it is also referred to as a three-phase motor, a three-phase machine, or an alternating current machine.

What Types of Three-Phase Motors Are There?

Squirrel-Cage Rotor, Slip-Ring Rotor, Rotating Field Magnet

Is Three-Phase Current the Same as High Voltage?

Three-phase current is equivalent to high voltage.

When is Three-Phase Current Needed?

Three-phase current is mainly used for the long-distance transmission of energy in power grids as well as for high-power devices such as ovens or electric vehicles.