Professional Planning – Essential for Control Cabinet Construction

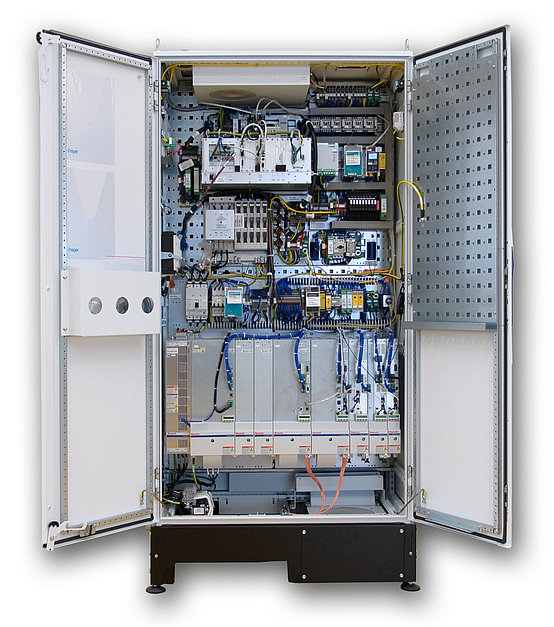

Control cabinets serve as control and switching centers for machinery and are primarily used in industry and building technology. A control cabinet is required when electronic components cannot be directly integrated into production or process technology systems.

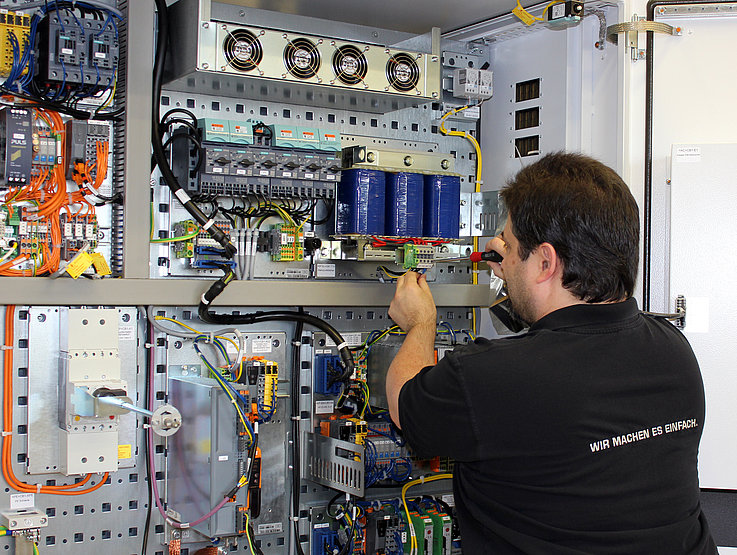

When planning a control cabinet, it's best to start with the design of the electronics that will be installed in the cabinet. The installation of all components must function smoothly. A CAD program helps in creating an appropriate circuit diagram.

Even during the planning phase, attention should be paid to electromagnetic compatibility (EMC).

Construction of a Control Cabinet

Control cabinet housings are typically made of powder-coated steel sheet, aluminum, stainless steel, or plastic.

In areas where cables and wires converge in an industrial context, a compact control cabinet provides a solution to ensure safety and protect cables, wires, machinery, and personnel.

The construction of control cabinets offers several advantages for the safe handling of cables and wires:

- Structured layout, no exposed cables

- Prevention of overheating

- Shielding against water, dust, and dirt

- Fire protection

- Protection against mechanical impacts

- Coverage against vandalism

- Shielding of electromagnetic emissions

Types of Control Cabinet Construction

There are various types of control cabinets:

- Floor-Standing Control Cabinets: These are standalone enclosures with one or more doors.

- Modular Control Cabinets: These cabinets lack side walls, allowing for mounting and access from all sides.

- Wall-Mounted Control Cabinets: Commonly used for applications such as fuse boxes, distribution boxes, surface-mounted and flush-mounted distribution panels, and meter cabinets.

- IT Racks: Designed for networking and server applications.

- Outdoor Control Cabinets: Typically made from aluminum with UV-resistant coating, stainless steel, or plastic. They are often double-walled to accommodate integrated ventilation systems.

- Over 90% of control cabinets are constructed using mounting panels.

Control Cabinet Construction with LQ

The LQ Group offers both standard and customized solutions. In addition to conventional cabinet assembly, we also provide modular control cabinet construction. According to the LQ philosophy, traditional point-to-point wiring is replaced by functional modules. This reduces complexity and provides high flexibility, characterized by the ease of replacing individual components.

Inquire Now